Resilience plus recyclability: our sustainable approach to beverage crates

Contact us

Get in touchResilience and recyclability go hand in hand for Schoeller Allibert's beverage crates, both serving a common purpose: sustainability.

With decades of experience in producing plastic packaging, Schoeller Allibert excels in creating strong and durable products, with minimal risk of defects and extended lifespans. In other words, our crates are resilient, significantly reducing the need for replacements and the demand for raw materials.

A beverage crate can have a lifespan of up to 30 years through continuous use and re-use. When it eventually reaches the end of that first life cycle, there is another life at the end of the tunnel. The beverage crate is fully recycled into a new one — a cradle-to-cradle approach to recycling.

By closing the loop, Schoeller Allibert drastically reduces the demand for new raw materials, aiming to achieve zero reliance on them. This is a significant development for industry as a whole, and for the packaging industry in particular. It enhances the sustainability of the entire supply chain, and helps save our environment.

Plus, this is a textbook example of how the synergy between economy and ecology brings mutual benefits. By reducing the need for new raw materials, which is both cost-effective and environmentally friendly. Schoeller Allibert takes pride in spearheading this doubly positive development, and we believe that our recyclability will set the industry standard.

Plus, this is a textbook example of how the synergy between economy and ecology can generate mutual benefits. Reducing the need for virgin raw materials eliminates a large part of the materials supply chain, including mining and transport. As such, recycling is not only a more sustainable solution in terms of the materials themselves, but also with regard to the machines and manpower needed to extract them.

If you're curious about how this all works: don’t worry, we got this. We collect used crates (and other containers), thoroughly clean and grind them, wash and dry the material, and finally remould it into brand-new crates, ready for use. No pollution, no waste!

And of course, our sustainable packaging cycle complies with all necessary food packaging safety standards. The European Food Safety Authority (EFSA) has provided scientific advice and approval for our recycling processes, which are carried out in our facilities located in the Netherlands, Germany, and Spain.

CASE STUDY

Circular economy: we walk the walk

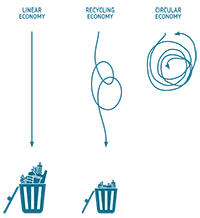

In a linear economy, raw materials are used once and then discarded as waste. We all know that’s not sustainable, so everybody is trying to do better. An important step is the one towards a recycling economy, in which materials are re-used as much as possible - but far from fully. The result: there is still waste, but there’s just less of it.

We are committed to the ideal of the circular economy, in which products are fully re-used, as many times as possible. This would protect resources, prevent waste, and significantly reduce carbon emissions.

It’s an ideal that, on a global scale, is still far off. According to the Circularity Gap Report 2021, just 8.6% of the 100 billion tons of resources the world consumes every year are recycled.

At Schoeller Allibert, we don’t just talk the talk, we walk the walk: all our boxes, beverage crates and containers are designed for a long life - and for many more lives after that first one.

Contact us

Get in touchContact us

Inspiration

Related

Est proident veniam laborum exercitation est veniam reprehenderit nostrud officia. Ad Lorem aliquip duis labore duis. Irure deserunt eu minim culpa eiusmod quis ut sint eu pariatur magna aliquip et incidid voluptate cillum Lorem amet ea.

Navigating EU Sustainability Regulations in Transport Packaging—A Roadmap for Compliance and Opportunity

We’re thrilled to introduce our latest whitepaper: New EU sustainability regulations and their impact on packaging. Designed as your essential resource, this whitepaper breaks down the complex, changing landscape of EU s...

Read newsMagnum Optimum Hopper® 1208, dispensing excellence for the beverage industry

Schoeller Allibert developed approximately 20 years ago the new foldable format, which has become a global standard in many sectors. Following the successful introduction of the Magnum Optimum Optishute® and Magnum Optim...

Read newsSchoeller Allibert: your automotive logistics partner – also for EVs!

Are you looking for an automotive logistics partner? Schoeller Allibert has got you covered. We have a long history of excellence in the industry, powered by a strong tradition of innovation. Which means that even if you...

Read news