Enhancing beverage crate design for products, brands and consumers

Contact us

Get in touchEnhancing beverage crate design for products, brands and consumers

Gone are the days of crude wooden boxes. Today, most beverage crates are made of plastic, and a lot of innovation has gone into their design, for the benefit of products, brands and consumers. Schoeller Allibert in particular has made a big difference in this area.

But why invest so much effort in designing better beverage crates? There are two key reasons:

Firstly, improved crate design helps products and brands to stand out. A unique and distinctive appearance sets your crates apart from competitors'. Eye-catching designs make an impact on retailer shelves, while special colours or shapes help consumers with locating your products.

Secondly, better design enhances the customer experience. Ergonomic features ensure easy and comfortable carrying. Novelty elements create talking points and further elevate the visibility and status of your brand and products.

In addition to appearance and experience, proper crate design is essential for logistics. Throughout the supply chain, from production to transport to retail, crates need to be strong, stackable, and capable of protecting their typically fragile contents. They must perform reliably in a variety of areas, from factory conveyor belts and to customer car trunks.

Schoeller Allibert has invested significant brainpower in designing the next-generation beverage crate. Some of the presentational design features we offer include:

Various material and colour combinations for both the exterior and interior of the crate.

Vibrant printing options with in-mould labels, including high-quality photo images.

Structured finish and embossing for excellent brand presentation.

Large side openings that allow for full display of contents.

Operational features of our crates include:

Soft-touch grips for enhanced carrying comfort.

Rounded, air-mold lamellas as a cost-effective alternative to soft-touch grips.

Middle handles for easy transportation.

While crate sizes are standardized, it doesn't mean they all have to be the same. By diversifying into "crate families," you can reach a broader target audience. Instead of the standard 20 x 0,5l or 24 x 0.33l crates, consider smaller crates for new launches, lowering the consumer threshold to try something new, and larger crates to cater to markets or segments with higher consumption rates.

CASE STUDIES

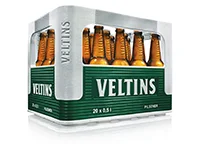

Veltins 20 x 0.5l

To distinguish its product from the competition, Veltins wanted a beverage crate with a clear and unique appearance. Using Schoeller Allibert’s innovative three-component technology, the new crate has a concise and functional appearance, with its impressive straight-lined form, well-rounded corners, wide opened handgrips, and a distinctive two-colour design.

Paulaner dividable crate

The Paulaner 20 x 0.5l crate can be divided into two separate crates of 10 bottles each by lifting the two golden handles upward towards the middle. This innovative approach allows the consumer to take home a smaller crate, if that serves their needs. At the same time, the standardized design ensures that these crates fit standard filling lines.

For more information, contact Schoeller Allibert.

Contact us

Get in touchContact us

Inspiration

Related

Est proident veniam laborum exercitation est veniam reprehenderit nostrud officia. Ad Lorem aliquip duis labore duis. Irure deserunt eu minim culpa eiusmod quis ut sint eu pariatur magna aliquip et incidid voluptate cillum Lorem amet ea.

Navigating EU Sustainability Regulations in Transport Packaging—A Roadmap for Compliance and Opportunity

We’re thrilled to introduce our latest whitepaper: New EU sustainability regulations and their impact on packaging. Designed as your essential resource, this whitepaper breaks down the complex, changing landscape of EU s...

Read newsNew modern magenta containers for Fedefarma

Fedefarma is a pharmaceutical cooperative that operates in the health field offering comprehensive services for pharmacies, providing solutions to improve competitiveness, profitability and enhancing the health role of t...

Read moreROPAC 50th anniversary

Originally, the company Métallurgie et Plastic SA used our actual site for drawing and rolling metal profiles. This production site also produced under Schoeller’s bottle crates license for the Swiss market before being ...

Read news