Here's why our beverage crates are the future

Contact us

Get in touchBeverage crates may have a long tradition, but don’t think they’re a thing of the past. In fact, they represent the future. As sustainability becomes a top priority, more and more producers are shifting away from single-use plastic or Tetra Pak, which cannot be reused, towards reusable options like glass bottles in plastic crates. Schoeller Allibert takes pride in playing its part, exemplified by one of our trend-setting achievement: the Corona Extra crate made from recycled maritime industry plastic waste.

Deposit schemes offer an ideal solution for closing the loop in the circular management of beverage packaging. Simply put, consumers pay a deposit when purchasing bottles and crates and receive a refund when returning the empties.

This system has already been successfully implemented in various countries, such as Germany's Pfand and the Netherlands' statiegeld systems. The keystone for this system are returnable glass bottles, which can be rinsed and re-used an indefinite number of times, rather than one-way glass bottles. This system has proven to be highly effective in reducing waste and facilitating the reuse or recycling of packaging (evidenced by a 96% retrieval rate in Denmark, for instance).

Deposit schemes serve as a catalyst for the adoption of more sustainable beverage packaging solutions, including the combination of glass bottles and plastic crates. Unfortunately, these schemes are not yet universal, with only around 50 countries and territories worldwide having implemented them. Even in Europe, they remain the exception rather than the norm.

The good news is that deposit schemes are gaining momentum in more countries. In Europe, this trend is partly driven by the EU's Single-Use Plastics Directive (SUPD), which sets targets for manufacturers to incorporate 30% recycled material in plastic beverage bottles by 2030 and for governments to separately collect 90% of these bottles by 2029.

With our expertise and experience, Schoeller Allibert is well equipped to assist other markets in transitioning from single-use to reusable beverage packaging. Our award-winning Corona crate serves as compelling evidence of our commitment.

In collaboration with Waste Free Oceans, we designed a crate for Corona, a beer brand owned by AB InBev, the world's largest brewing group. A significant portion of the crate is made from recycled fishing gear. In other words: every crate means the ocean is a little bit cleaner.

So, Schoeller Allibert not only leads the industry in returnable plastic packaging but also excels in recycling used plastics. We take pride in being part of the solution and are dedicated to expanding our role, year after year – with the help, and for the benefit, of our customers.

Schoeller Allibert wouldn’t be the forward-thinking, customer-oriented one-stop-shop that we are if we didn’t also offer essential adjacent solutions to our beverage crate customers. Such as:

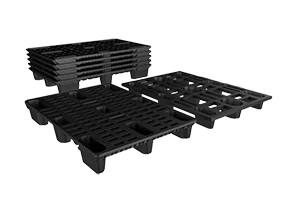

Pallets.

We offer a wide range, in a variety of dimensions, top decks and base configurations, with or without safety rim. With that much choice, we certainly have the ideal solution for your logistical requirements.

Hopper and Optishute.

As the name suggests, the Magnum Optimum® Hopper has a hopper base. The Magnum Optimum® Optishute has a translucent door. That makes these foldable large containers ideally suited for the bottle caps industry, which requires those caps to be supplied at a regular flow.

Locator boards.

As a cost-effective alternative to flat and yoke pallets in terms of transport and warehousing, locator boards have become a common handling system in beverage distribution. Over the years, the design of locator boards has improved and sizes have been rationalized. By reducing the manual effort needed to move the pallets, they’re also safer to operate.

Contact us

Get in touchContact us

Inspiration

Related

Est proident veniam laborum exercitation est veniam reprehenderit nostrud officia. Ad Lorem aliquip duis labore duis. Irure deserunt eu minim culpa eiusmod quis ut sint eu pariatur magna aliquip et incidid voluptate cillum Lorem amet ea.

Navigating EU Sustainability Regulations in Transport Packaging—A Roadmap for Compliance and Opportunity

We’re thrilled to introduce our latest whitepaper: New EU sustainability regulations and their impact on packaging. Designed as your essential resource, this whitepaper breaks down the complex, changing landscape of EU s...

Read newsAttached lid containers at El Corte Ingles

Since 1995 Schoeller Allibert has been developing bespoke, safe & secure, sustainable ALC retail solutions for Spanish high street stores company El Corte Ingles. The first model was designed and used for non-food produc...

Read morePlastic pallets at Gekäs Ullared

Founded in 1963 Gekäs Ullared is Scandinavia's largest department store. Clothing, household goods, linen, accessories, health & beauty products... anything can be found at Gekäs. With 4,5 Million visitors per year, and ...

Read more